A key differentiator that puts the 3Doodler PRO pen above the rest of our 3D printing pens is the vast array of specialty materials that it’s compatible with. Designed for engineers, architects, designers, artists, and more, this pen has something to offer to each professional in their niche.

With the introduction of new Wood filament colors, we’ve put together a summary of the characteristics of each specialty material (wood, nylon and metals), along with some tips and tricks from Cornelia Kuglmeier, which you might find useful for all types of 3D pen designs.

Wood

Characteristics

Made with real wood fibre, this material carries a mild and natural wood aroma, and creates a sandy surface appearance when Doodled. Like any wooden material, it can be sanded down to reveal a cleaner finish. You could even stain the wood to give it a darker shade or to accentuate details in certain parts of your design.

Uses

Wood filaments, are favored by architects who want to add some life-like aesthetic to models, loved by sculptors to make figurines that add a warm feeling to interior decor, and used by the everyday handyman for repairs on wooden furniture, floors, utensils and more.

Doodling Technique

By popular demand, we’ve added 3 new color options (Cherry, Birch and Walnut) (link to AMZ Wood bundle) in addition to the existing Natural shade, to allow for more variety in creations! All Wood filaments have the same characteristics when in use.

The ideal settings for Wood is:

Temp: 170°C – 200°C (338°F – 392°F) / Speed: 3-6

Coating a structure that is pre-built with ABS or PLA plastic.

Making flat pieces to assemble together.

To make small, delicate pieces, we recommend using speed 1 or 2 to keep the plastic soft and fluid, making it easier to draw finer details, plus adjusting the fan speed allows you to control how fast/slow the plastic hardens.

Nylon

Characteristics

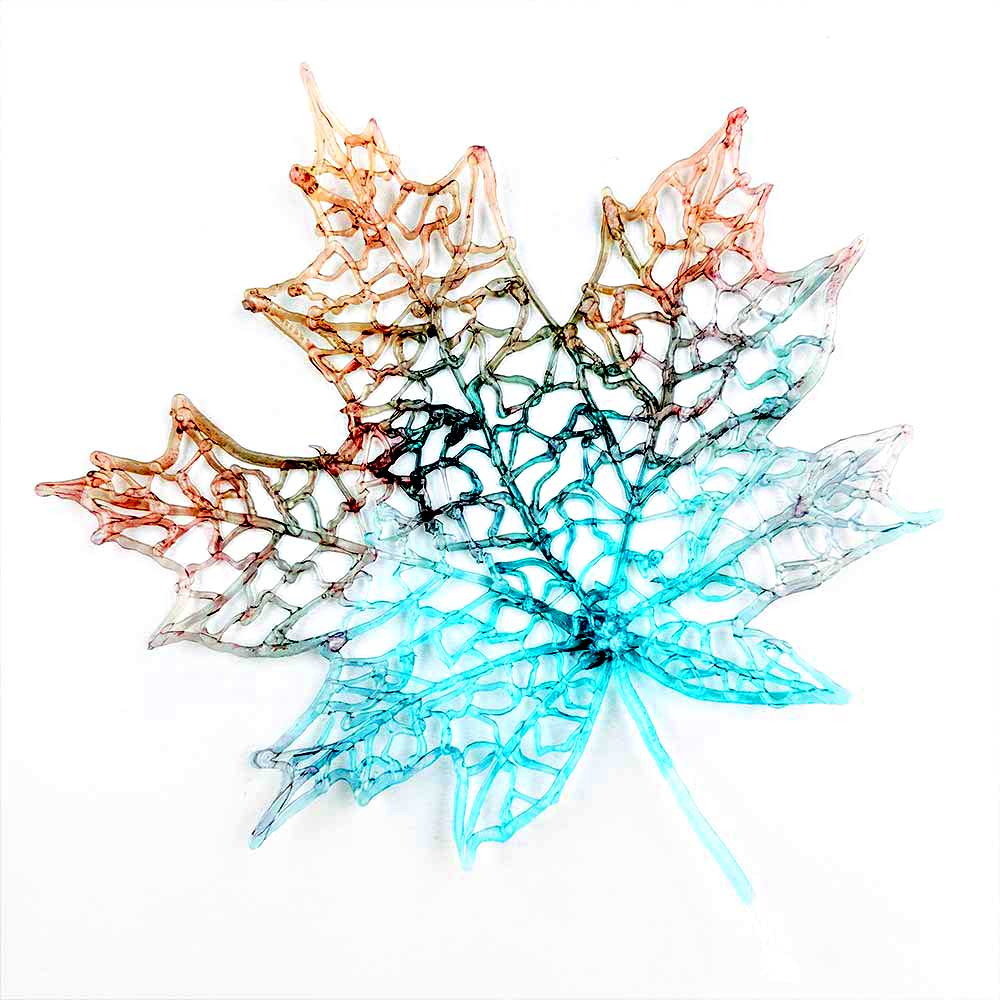

Nylon creates a very interesting fabric-like texture with a semi-translucent appearance. When extruded, the material forms sturdy strands that are bendable, but strong enough to hold their structural shape.

Uses

Designers love using Nylon to make an entire fashion accessory, outfit, or create embellishments to add decorative details to plain items. You could also make stylish home decor with this material, such as subtle wall art made up of dandelions.

Doodling Technique

Although Nylon is only available in one color, you can use fabric dye or food coloring to add some interesting effects to your final design. Here’s an example, using food coloring, of how you can create a beautiful color blending effect.

The ideal settings for Nylon is:

Temp: 200°C – 225°C (392°F – 437°F) / Speed: 3-6 / Fan: medium-high

Making functional parts or free-form structures.

Developing prototypes of clothing designs.

When joining nylon to nylon, we recommend turning the pen temperature up to 230°C – 240°C and fan to low, speed to 2 or 3. This helps to create extrusions that harden slower, and are therefore more sticky so you can create stronger connection points. Also, make sure to press the pen firmly onto the Doodled pieces to secure the joint.

Mix up your technique and use extruded Nylon filament to weave, crochet or braid to fabricate unique textures.

Metal

Characteristics

Bronze and Copper filaments allow you to create 3D structures which can be polished in different ways to get a premium-looking metallic finish. When left untreated, the metals have a clay-like appearance, which is unique in its own way.

Uses

Working with metal offers a very unique experience both while you Doodle, and after. It is ideal for making jewelry pieces and sculptures which may have otherwise required special tools and techniques to create.

Doodling Technique

The ideal settings for both Bronze and Copper is:

Temp: 180°C – 200°C (356°F – 392°F) / Speed: 3-5 / Fan: High

Doodle two to three layers to increase the strength of your creation, as these materials are brittle if using a single layer only.

For larger pieces, you can create a base structure in ABS or PLA to enhance rigidity.

For flat pieces, or pieces with a bigger surface, you can polish with sand paper to achieve a shinier and smoother finish. Start with a rough grit (e.g. 400 grit) to get rid of the overall roughness, then progress to a very fine grit (e.g. 1200 grit) to achieve next-level shine and shimmer. We recommend using wet sanding paper, or polishing paste. Finish off with steel wool.

For smaller creations with more crooks and edges, you can use the tumble finishing technique to give it an even more polished look. Fill the barrel with brass screws, put your Doodled piece in and let the machine do its work. Make sure to check on your piece from time to time, to see if it’s been damaged, if so, fix it then return to the tumbler. You will see the effects of this technique after about an hour of tumbling.

If the pen has trouble extruding metal filament, we recommend putting the pen on reverse, instead of pushing the filament through by force. If you can’t grip the strand as it is too short, adjust the pen temperature to 130°C, screw off the nozzle tip, then put the pen on reverse again and gently push the plastic out with the cleaning tool provided. Screw the nozzle back on to continue your work.

If you’d like to learn more about the different materials or the 3Doodler PRO pen itself, be sure to check out our dedicated product page.